Cooling towers are an essential piece of equipment in many industrial processes, playing a crucial role in maintaining optimal operating conditions for various applications. These towering structures are ubiquitous in power plants, manufacturing انواع برج خنک کننده, and other industrial settings where large amounts of heat must be dissipated efficiently. Let’s delve into the inner workings, types, and significance of cooling towers in today’s industrial landscape.

Understanding the Function

At its core, the primary function of a cooling tower is to remove excess heat from a system by transferring it to the atmosphere. This is achieved through the process of evaporation. Hot water or other process fluids are circulated through the tower, where they come into contact with a stream of air. As the water evaporates, it releases heat energy, thereby cooling down the remaining water or fluid.

Types of Cooling Towers

Cooling towers come in various shapes, sizes, and designs, tailored to suit specific industrial requirements. The two main classifications of cooling towers are:

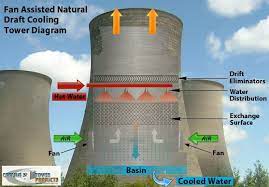

- Natural Draft Cooling Towers: These towers utilize the principle of buoyancy to draw air through the tower, facilitating the cooling process. They are characterized by their towering height and large concrete structures. Natural draft towers are often employed in large-scale power plants and heavy industrial applications.

- Mechanical Draft Cooling Towers: Unlike natural draft towers, mechanical draft towers employ fans or blowers to force air through the tower, enhancing the rate of heat transfer. They are typically more compact and versatile, making them suitable for a wide range of industrial applications. Mechanical draft towers can be further categorized into two types:

- Induced Draft Cooling Towers: In these towers, fans are located at the top of the tower, creating a negative pressure zone that draws air through the tower.

- Forced Draft Cooling Towers: Here, fans or blowers are positioned at the base of the tower, pushing air upwards through the tower.

Significance in Industrial Processes

The significance of cooling towers in industrial processes cannot be overstated. Here are some key reasons why cooling towers are indispensable:

- Temperature Control: Cooling towers play a vital role in maintaining optimal operating temperatures for various industrial equipment and processes. By dissipating excess heat, they prevent equipment overheating and ensure efficient operation.

- Energy Efficiency: Efficient cooling tower operation can significantly reduce energy consumption in industrial facilities. By utilizing the natural process of evaporation, cooling towers offer a cost-effective means of heat dissipation compared to mechanical refrigeration systems.

- Environmental Impact: Cooling towers help mitigate the environmental impact of industrial processes by reducing the discharge of heated water into natural water bodies. This helps prevent thermal pollution, which can have detrimental effects on aquatic ecosystems.

- Process Reliability: In many industrial processes, maintaining consistent temperatures is critical for product quality and process reliability. Cooling towers provide a reliable means of heat removal, helping ensure stable operating conditions.

- Water Conservation: While cooling towers consume water for the evaporation process, they often facilitate water conservation by enabling the reuse of process water. By cooling and recirculating water, cooling towers minimize the need for fresh water intake, particularly in water-scarce regions.

Conclusion

In conclusion, cooling towers are indispensable components of industrial cooling systems, playing a vital role in temperature control, energy efficiency, and environmental sustainability. Whether in power plants, manufacturing facilities, or chemical processing plants, these towering structures serve as the backbone of countless industrial processes, ensuring